Sheet Metal Fabrication Supports the Development of Custom Industrial Machinery

Custom industrial machinery is designed to meet specific production or operational needs in different industries. These machines often require specialized parts, custom components, and durable materials to perform unique functions. Sheet metal fabrication plays a key role in supporting the development of such machinery. Its ability to deliver precise, tailored, and durable components helps manufacturers create machines with optimized performance. Whether it is a conveyor, enclosure, or housing, sheet metal solutions ensure efficiency, flexibility, and structural strength in the equipment-building process.

The Role of Sheet Metal Fabrication

TZR sheet metal fabrication contributes to custom industrial machinery in various practical ways:

- Custom design flexibility: Sheet metal can be cut, bent, welded, and shaped into specific forms to match the design of unique machines.

- Compatibility with automation: Fabricated components fit precisely with automation systems, sensors, and moving parts.

- Strength and durability: Sheet metal provides long-lasting structural integrity, even in high-stress or high-temperature environments.

- Cost-efficiency for prototypes and production: Custom components can be made in small or large quantities, supporting both one-off designs and mass production.

The Benefits for Machinery Builders

Using sheet metal in machinery development offers a range of important benefits:

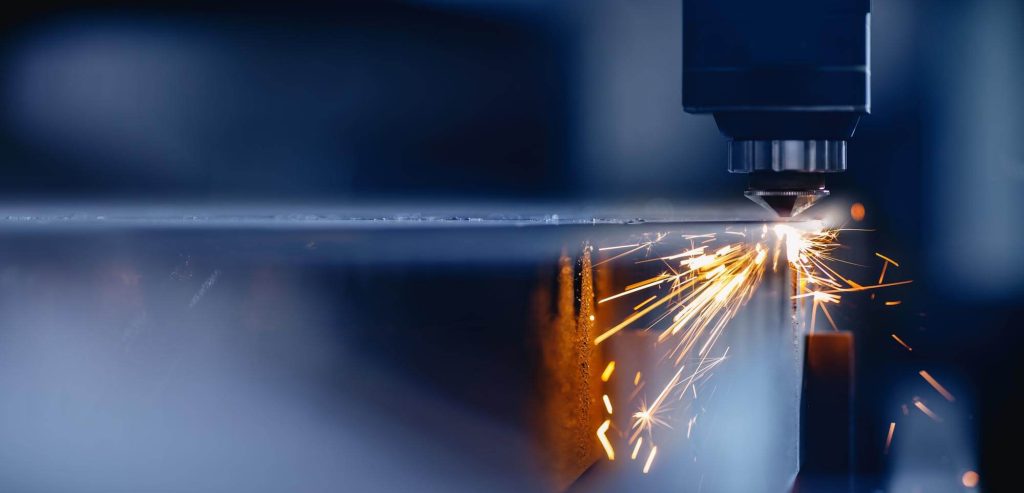

- Precision engineering: Advanced CNC cutting and laser technology allow for highly accurate parts.

- Speed of production: Rapid fabrication methods reduce lead time and speed up the overall machine-building process.

- Material variety: Metals like stainless steel, aluminum, and carbon steel provide various mechanical properties suited for different environments.

- Easy modification: Sheet metal parts can be adjusted or redesigned without major delays, making them ideal for evolving projects.

Applications Across Machinery Types

Sheet metal fabrication supports numerous types of custom industrial machinery, such as:

- Food processing equipment – Hygienic stainless steel structures.

- Packaging machines – Lightweight, corrosion-resistant panels and frames.

- Pharmaceutical and medical equipment – Precision housings and guards.

- Automotive manufacturing machinery – Strong parts for robotic arms and conveyors.

- Electronics assembly machines – Custom brackets and cooling enclosures.

Final Thoughts

Sheet metal fabrication is essential in building custom industrial machinery. Its adaptability, strength, and compatibility with modern manufacturing tools make it a go-to solution for machine designers and engineers. From simple parts to complex assemblies, sheet metal helps turn innovative machinery concepts into functional, real-world equipment. This support ensures that industries can operate with machines built specifically for their needs, enhancing productivity and long-term performance.

- Sheet metal fabrication allows for custom-built components for industrial machines.

- It provides precision, durability, and material flexibility.

- It supports both prototyping and full-scale manufacturing.

- Widely used in industries such as food, medical, automotive, and electronics.

- Enables cost-effective, reliable, and scalable machinery development.